High Pressure Laminate and Thermally Fused Laminate: Understanding the Differences

This Q&A will help you understand how HPL and TFL differ, and where each works best for interior surfacing.

HPL vs. TFL

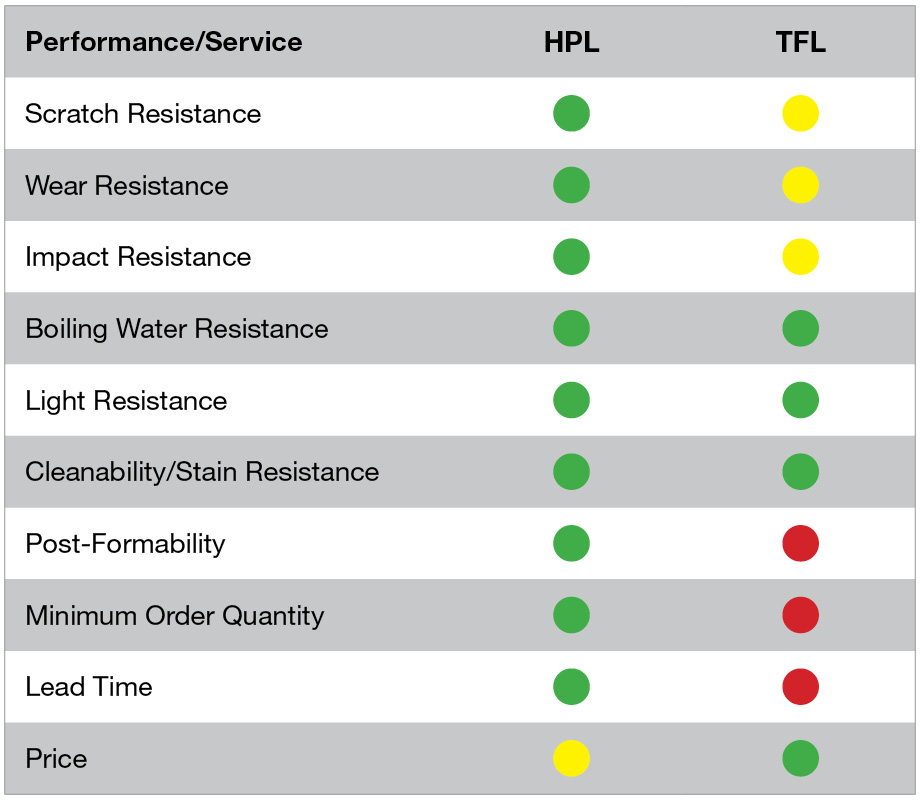

There’s been some buzz in the manufacturing and design industry lately regarding the differences between high pressure laminate (HPL) and thermally fused laminate (TFL). From a performance standpoint, these two options aren’t equal, and it’s important to understand how to select the right laminate material for client projects.

What is high pressure laminate (HPL)?

High pressure laminate (HPL) is specifically engineered for both horizontal and vertical applications due to its durability and impact resistance. HPL is made from multiple layers — surface papers treated with melamine resin and core kraft papers treated with phenolic resin. These are fused together under high temperature and pressure to become a thermoset laminate sheet, which is then applied to a substrate, like medium density fiberboard (MDF).

What are the benefits of HPL?

HPL’s multi-layer composition generates category-best scratch resistance, wear resistance and impact resistance. Additionally, HPL is easy to clean and can be postformed to add flexibility in design. Formica® high pressure laminate sheets have low minimum order quantities and fast lead times to help designers keep projects on track.

What is thermally fused laminate (TFL)?

TFL is a value-engineered alternative to HPL in some vertical applications. This decorative paper is treated with melamine resins and pressed directly to a substrate. It’s often used for cabinets and office furniture. TFL has significantly lower scratch resistance, wear resistance and impact resistance compared to HPL.

What are the benefits of TFL?

TFL is a true value play. It’s a good choice when durability isn’t a major concern, and budgets are tight.

When should HPL and TFL be used?

HPL should be used when a durable, high-performance surface is needed. It is also the only choice if postforming is required. HPL has a shorter lead time and much smaller minimum order quantities compared to TFL, making project timelines a factor in decision-making. TFL replace wood veneers and other surface materials in low-traffic areas where scratch resistance and impact resistance aren’t key factors.